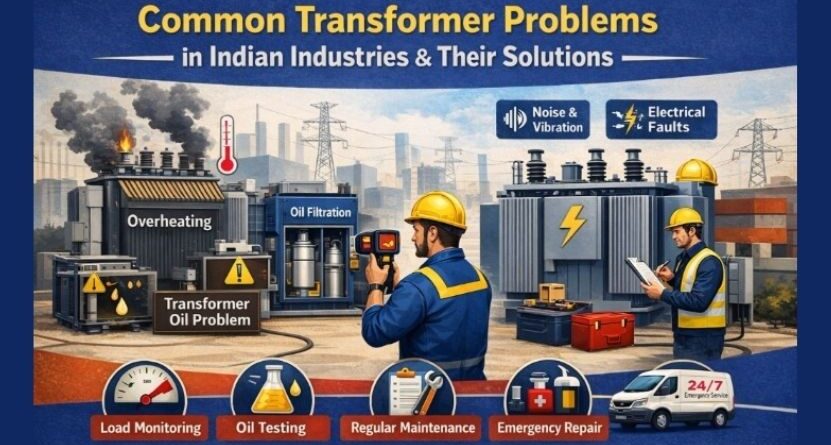

Common Transformer Problems in Indian Industries and Their Practical Solutions

Electric_Admin2026-02-05T11:04:51+00:00Transformers are the backbone of industrial power distribution in India, ensuring smooth electricity flow for manufacturing plants, factories, and industrial units. However, even the most robust transformers face operational challenges that can disrupt production, increase costs, and pose safety hazards. Understanding common transformer problems in industries is essential for plant managers, engineers, and maintenance teams to mitigate downtime and improve efficiency. In this blog, U.K Electric Co. highlights the most frequent transformer issues in Indian industries and offers practical solutions based on decades of experience.

Common Transformer Faults in Indian Industries

In industrial environments, transformers are subjected to high loads, temperature fluctuations, and environmental stresses. Identifying transformer problems in Indian industries early can prevent catastrophic failures.

Transformer Overheating Problems

One of the most critical challenges in industrial transformers is transformer overheating problems. Overheating can occur due to overloading, poor ventilation, or insulation degradation.

Causes:

- Excessive load beyond transformer capacity

- Accumulated dust or debris is blocking cooling mechanisms.

- Old or contaminated transformer oil

- Faulty cooling fans or radiators

Solutions:

- Monitor load regularly to prevent overloading

- Ensure proper ventilation around transformer units.

- Implement regular oil testing and filtration.

- Maintain cooling systems effectively.

U.K Electric Co. specialises in industrial transformer overheating causes and solutions, offering both preventive maintenance and emergency responses.

Transformer Oil-Related Problems

Transformer oil is crucial for insulation and cooling. Transformer oil-related problems like contamination, moisture ingress, and sludge formation can lead to insulation failure and winding damage.

Common issues include:

- Transformer oil contamination problems in factories

- Degradation of dielectric properties

- Oil leakage leading to fire hazards

Preventive Measures:

- Routine oil filtration and dehydration services

- Immediate repair of any oil leakage

- Regular testing of the oil dielectric strength

By using advanced filtration plants, U.K Electric Co. ensures optimal oil quality, extending transformer life and preventing electrical transformer failure.

Transformer Maintenance Issues

Neglecting maintenance is one of the leading causes of industrial transformer faults. Poorly maintained transformers can experience insulation breakdown, winding damage, and increased risk of electrical failures.

Key Maintenance Challenges:

- Transformer winding failure causes

- Insulation deterioration due to moisture or overheating

- Noise and vibration issues indicating mechanical or electrical faults

Maintenance Tips:

- Schedule periodic inspection and testing

- Implement transformer maintenance tips for industries.

- Use professional transformer repair services to address minor issues before they escalate.

Electrical Transformer Failure Reasons in Factories

Understanding the root causes of failures allows industries to adopt proactive strategies. Electrical transformer failure reasons are often a combination of operational stress, environmental factors, and human error.

Common Causes:

- Overloading beyond rated capacity

- Poor or irregular transformer maintenance

- Transformer trip problem in the factory due to short circuits or faults

- Oil contamination or insulation degradation

- Mechanical stresses cause winding deformation.

U.K Electric Co. offers comprehensive electrical transformer repair services and emergency troubleshooting to minimise downtime and prevent prolonged production halts.

Transformer Noise and Vibration Problems

Industrial transformers can develop a transformer noise humming problem in industries, often caused by loose laminations, vibration, or electrical imbalances. While sometimes minor, persistent noise can indicate deeper issues like core displacement or winding instability.

Solutions Include:

- Tightening structural components

- Checking for loose windings or connections

- Employing vibration dampers if needed

- Conducting a detailed diagnostic with professional Transformer Repairing Services

Power Transformer Common Problems in Industrial Units

Power transformer common problems in manufacturing plants and industrial units include:

- Transformer Winding Failure Causes: Often triggered by overloading, short circuits, or insulation wear.

- Transformer Insulation Failure Reasons: Due to moisture, oil contamination, or thermal stress.

- Transformer Oil Leakage Problem and Solution: Leaks can be stopped with proper sealing and prompt oil replacement.

- Industrial Transformer Overheating Causes and Solutions: Overheating can be managed by load optimisation and regular oil maintenance.

- Transformer Trip Problem in Factory: Triggered by overload, fault current, or relay malfunctions; requires expert intervention.

Professional assessment by U.K Electric Co. ensures long-term reliability and safety of power transformers in industrial operations.

Transformer Repair and Emergency Solutions

Unexpected transformer breakdowns can halt production, leading to financial losses. Knowing what to do when an industrial transformer fails is crucial.

Immediate Actions:

- Shut down the transformer to prevent further damage.

- Inspect for signs of overheating or oil leakage.

- Contact certified industrial transformer repair services in India

U.K Electric Co. provides emergency power transformer repair services, offering on-site troubleshooting, oil filtration, winding repairs, and testing to restore normal operations swiftly.

Preventive Measures to Avoid Transformer Failures

Preventing failures is always more cost-effective than repair. Here’s a checklist of transformer maintenance problems in India and how to address them:

- Regular Oil Testing and Filtration: Prevents transformer oil contamination problems in factories.

- Routine Inspection of Windings and Insulation: Reduces the risk of transformer winding failure causes.

- Monitoring Load and Temperature: Avoids transformer overheating emergency solution scenarios.

- Professional Transformer Maintenance Services: Engaging certified providers like U.K Electric Co. ensures compliance with safety standards and extends transformer lifespan.

Additional industrial transformer repair and maintenance guide steps include vibration analysis, thermal imaging, and testing the dielectric strength of insulating oil.

Common Transformer Problems in Manufacturing Plants

Manufacturing plants are particularly vulnerable to transformer issues due to high load demand. Some recurring problems include:

- Frequent trips and power transformer issues in industrial units

- Noise and vibration are disrupting sensitive machinery.

- Oil leaks and reduced dielectric strength lead to insulation breakdown.

How to Prevent Failures in Factories:

- Conduct regular preventive maintenance

- Train staff to identify signs of transformer failure in industries

- Schedule timely transformer repair services in India to avoid major damage

Benefits of Professional Transformer Repair Services

Professional intervention is critical for resolving industrial transformer faults. Certified services offer:

- Accurate diagnostics for electrical transformer problems in factories

- Preventive maintenance to avoid recurrent failures

- Emergency response for transformer overheating in industries

- Expertise in industrial transformer repair services in India for all makes and capacities.

U.K Electric Co. has decades of experience repairing transformers up to 25 MVA and 132 KV, making them a trusted partner for industrial units seeking reliable Transformer Repairing Services.

Solutions for Industrial Transformer Oil Problems

Oil-related issues are among the most common in transformers. Effective solutions include:

- Filtration and Dehydration: Remove moisture and contaminants to maintain oil quality

- Leak Repairs: Seal minor leaks before they escalate

- Regular Monitoring: Ensure consistent dielectric strength to prevent insulation breakdown

Following these practices prevents transformer oil contamination problems in factories and extends the operational life of the transformer.

Industrial Transformer Overheating Causes and Solutions

Overheating is both a cause and a symptom of transformer stress. Key preventive actions:

- Avoid overloading beyond rated capacity

- Ensure proper oil circulation and cooling system maintenance.

- Conduct periodic thermal imaging inspection.

- Implement corrective actions immediately if signs of transformer failure in industries appear.

U.K Electric Co. provides guidance on how to fix transformer overheating in industries, ensuring safety and an uninterrupted power supply.

Conclusion

In Indian industries, understanding and addressing common transformer problems in industries is vital for smooth operations, safety, and cost management. From industrial transformer overheating causes and solutions to transformer oil contamination problems in factories, timely intervention prevents prolonged downtime and costly repairs.

Professional support from experienced providers like U.K Electric Co. ensures that your transformers receive expert maintenance, emergency repairs, and preventive care. By adopting proper maintenance routines, monitoring operational loads, and addressing minor issues promptly, factories can significantly reduce the risk of electrical transformer failure and maximise efficiency.

Take action today by contacting U.K Electric Co. for comprehensive transformer repair services or visit our Google Business Profile to learn more about how we can help protect your industrial transformers and maintain uninterrupted operations.

FAQs on Industrial Transformer Issues in India

Common issues include overheating, oil contamination, insulation failure, winding damage, noise, and frequent trips in industrial units.

Ensure proper load management, regular oil filtration, ventilation, and timely cooling system maintenance to prevent overheating emergencies.

Moisture, dust, sludge formation, and oxidation degrade transformer oil, reducing insulation and cooling efficiency.

Frequent trips, unusual noise, overheating, oil leakage, and voltage fluctuations indicate impending failure.

Routine inspections, oil testing, and mechanical checks every 6–12 months help prevent breakdowns and prolong transformer life.

Moisture ingress, overheating, overloading, and poor oil quality lead to insulation breakdown in transformers.

Yes, professional industrial transformer repair services in India can handle oil filtration, winding repairs, and mechanical fixes on-site.

Seal the leak immediately, replace or filter the contaminated oil, and inspect insulation for damage.

Shut down the unit, inspect for overheating or leaks, and contact certified transformer repair services like U.K Electric Co.

Persistent noise may indicate winding or core issues; prompt inspection prevents mechanical or electrical failure.