How to Prevent Transformer Failure: Complete Maintenance Guide for Industries

Transformers are one of the main power supply devices that keep the power flowing in industrial and commercial facilities. A failure of even one transformer can cause a stoppage of production, leading to loss of money, damage to other equipment, and even danger to people.

It is a known fact that it is not the age of the transformer that causes most of the breakdowns, but factors like lack of proper maintenance, oil contamination, overloading and absence of timely testing.

Proper inspection, periodic testing, oil maintenance, and professional servicing can all be used as means of preventing a transformer failure. This thorough maintenance guide shows how industries can safeguard their transformers and guarantee dependable, long-lasting performance.

Understanding the Main Causes of Transformer Failure

Before implementing preventive measures, it is important to understand what causes transformer failure:

- Overloading beyond rated capacity

- Insulation breakdown

- Moisture contamination in transformer oil

- Poor electrical connections

- Winding faults

- Inadequate cooling

- Lack of regular testing and maintenance

Identifying these issues early through professional transformer repair services can prevent major breakdowns.

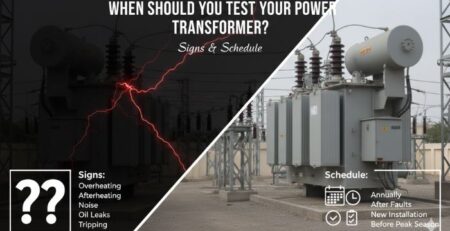

1. Schedule Regular Transformer Testing

Routine testing is essential to detect internal faults before they turn into serious problems.

Important Transformer Testing Includes:

- Insulation Resistance (IR) Testing

- Turns Ratio Testing

- Winding Resistance Testing

- Oil BDV Testing

- Dissolved Gas Analysis (DGA)

- Load Testing

Professional transformer testing service helps monitor insulation strength, internal heating, and overall transformer health.

Recommended Frequency: At least once per year, or more frequently for heavily loaded industrial transformers.

2. Maintain Transformer Oil Quality

Transformer oil acts as both a coolant and an electrical insulator. If oil quality deteriorates, the transformer becomes vulnerable to overheating and insulation failure.

Common Oil Problems:

- Moisture contamination

- Sludge formation

- Reduced dielectric strength

- Oxidation

Regular transformer oil filtration services and transformer oil dehydration and filtration services remove moisture, gases, and impurities, restoring oil performance.

Tip: Conduct oil testing every 6–12 months for industrial transformers.

3. Avoid Overloading the Transformer

Overloading significantly reduces transformer lifespan. When a transformer operates above its rated capacity:

- Internal temperature rises

- Insulation degrades faster

- Risk of short circuit increases

Install load monitoring systems and ensure the transformer is properly rated for your operational requirements.

If additional capacity is required temporarily, businesses can opt for a transformer on rent or a transformer on hire instead of stressing existing equipment.

4. Implement Preventive Maintenance Programs

Preventive maintenance is the most effective way to avoid unexpected failures.

A Proper Maintenance Plan Includes:

- Visual inspection of external components

- Tightening electrical connections

- Cleaning radiators and cooling systems

- Checking bushings and gaskets

- Thermographic scanning

- Oil level inspection

Professional transformer repair & maintenance services ensure that small issues are resolved before they become costly repairs.

5. Perform Timely Transformer Rewinding

Winding failure is one of the most serious internal transformer issues.

Signs That Rewinding May Be Required:

- Burning smell

- Repeated tripping

- Abnormal humming noise

- Excessive heating

- Low insulation resistance

Professional rewinding services of transformers restore electrical performance and extend equipment life at a lower cost compared to replacement.

6. Consider Transformer Overhauling for Aging Units

For older transformers, periodic overhauling improves efficiency and reliability.

Transformer overhauling services typically include:

- Internal inspection

- Core and winding examination

- Replacement of worn gaskets

- Oil replacement or filtration

- Cleaning and tightening of components

Overhauling reduces the risk of sudden breakdown and enhances operational safety.

7. Keep Emergency Repair Support Ready

Even with preventive maintenance, emergencies can occur. Partnering with a reliable transformer repair company ensures a quick response and minimal downtime.

Fast and professional power transformer repair services can prevent minor faults from turning into major failures.

8. Replace or Upgrade Old Transformers When Necessary

Very old transformers may become inefficient and unsafe to operate.

Businesses should evaluate whether to:

- Repair

- Rewind

- Overhaul

- Purchase a replacement

- Sell under the old transformers, sale and purchase

Making timely decisions prevents operational disruption and long-term losses.

Preventive Maintenance Checklist for Industrial Transformers

- Annual electrical testing

- Regular oil filtration and dehydration

- Load monitoring

- Thermal scanning

- Tightening of connections

- Cooling system cleaning

- Periodic internal inspection

- Professional repair support

Following this checklist significantly reduces the chances of transformer failure.

Benefits of Preventing Transformer Failure

Investing in preventive maintenance offers multiple advantages:

- Reduced downtime

- Lower repair costs

- Extended transformer lifespan

- Improved energy efficiency

- Enhanced workplace safety

- Increased operational reliability

Preventive maintenance is always more cost-effective than emergency repairs.

Conclusion

Transformer failure can cause huge losses in terms of money and disruption to the working of industries. Yet, transformer testing, oil filtration, rewinding, overhauling, and preventive maintenance can help in avoiding at least 90% of the failures.

The reliable functioning of your transformer over a long period of time, safe and energy-efficient operation can be ensured only by the regular servicing of experienced professionals.

In case your industry is in need of expert transformer repairing services, oil filtration, testing, rewinding, rental, or overhauling, make sure that you work with a trustworthy and experienced service provider so that power performance is always maintained without any hiccup.