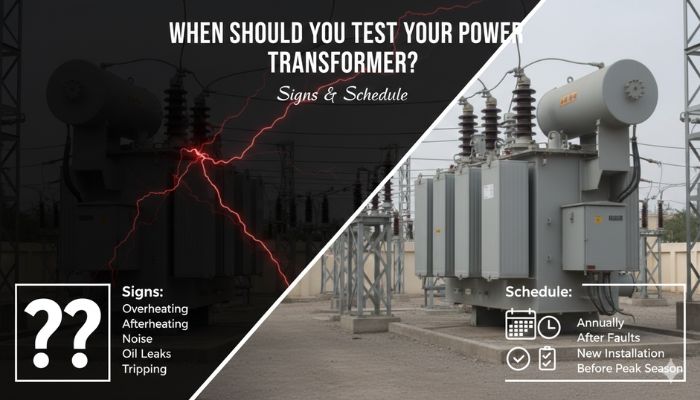

When Should You Test Your Power Transformer? Signs and Schedule

Power distributors and power-generating industries, as well as commercial facilities, have power transformers that are important assets. They are good in terms of reliability,y in terms of voltage conversion and uninterrupted operations. Nevertheless, transformers also age, wear, and suffer other environmental pressures like any other electrical equipment. It is necessary to test regularly to identify issues at an earlier stage, avoid failure, and increase service life.

The following article will discuss when you should test your power transformer, what warning signs you should be aware of and how the testing is supposed to be carried out.

Why Transformer Testing is Important

Transformer testing assists in assessing the well-being, security and execution of the machinery. With time, the insulation can wear out, the oil can spoil, andthe internal parts can be worn out. Small problems may eventually end up being a big failure when they are not properly tested, leading to expensive downtime and loss of lives.

Regular inspection and testing help:

- Detect insulation failure early

- Prevent unexpected breakdowns

- Improve transformer efficiency

- Extend equipment lifespan

- Ensure safe and reliable operation

Professional Power transformer testing Services can identify hidden faults using advanced diagnostic methods and ensure your equipment operates safely.

Warning Signs That Your Transformer Needs Testing

You should immediately test your transformer if you notice any of the following warning signs:

1. Overheating

One of the most typical signs of transformer issues is excessive heat. The overloading can cause overheating or the destruction of insulation or the failure of the cooling system. In case of an increase in the temperature of the transformer beyond the standard level, it should be tested.

2. Unusual Noise

Transformers are known to have a low humming noise. Nevertheless, loud buzzing, crackling, or strange sounds can suggest internal defects, loose elements or the breakdown of insulation.

3. Oil Leakage

The transformer oil is very important in cooling and insulation. The oil leakage decreases the insulation strength and the possibility of failure and overheating. When leakages are noticed, oil testing should be done as soon as possible.

4. Frequent Tripping or Protection Activation

When your transformer trips or protection systems go off on a regular basis it could be due to internal faults, overload or insulation.

5. Voltage Fluctuations

Volatile output voltage may cause issues on other connected equipment and could be a sign of winding damage or internal transformer issues.

6. Ageing Transformer

Transformers above 1015 years old need to be tested more frequently to be monitored in terms of insulation condition and general performance.

These signs should never be ignored, especially if you are planning an Old Transformers Sale And Purchase, as proper testing ensures accurate condition assessment and fair valuation.

Recommended Transformer Testing Schedule

A regular testing schedule helps maintain transformer reliability and performance.

Routine Testing (Every 6 to 12 Months)

Routine tests include:

- Oil quality testing

- Visual inspection

- Temperature monitoring

- Insulation resistance testing

These tests help identify early-stage issues.

Annual Testing

Annual testing provides a more detailed assessment and may include:

- Insulation resistance test

- Winding resistance test

- Oil dielectric strength test

- Transformer turns ratio test

These tests ensure the transformer is operating within safe limits.

Major Diagnostic Testing (Every 3 to 5 Years)

Comprehensive diagnostic testing helps detect deeper internal issues. These tests include:

- Dissolved Gas Analysis (DGA)

- Tan Delta test

- Sweep Frequency Response Analysis (SFRA)

- Partial discharge testing

These advanced tests provide detailed information about transformer health.

Testing After a Fault or Major Event

You should always test your transformer after:

- Electrical faults

- Lightning strikes

- Short circuits

- Overloading incidents

- Long storage periods

This ensures the transformer is safe before returning to service.

Testing Before Installation or Relocation

Transformers should also be tested before installation, relocation, or commissioning. This confirms there is no damage during transportation or storage.

Testing is especially important when dealing with used equipment to ensure safe operation and reliability.

Benefits of Regular Transformer Testing

Regular transformer testing provides several long-term benefits:

- Reduces risk of unexpected failure

- Improves operational reliability

- Extends transformer lifespan

- Minimizes maintenance costs

- Ensures safety and compliance

Preventive maintenance is always more cost-effective than emergency repairs or replacement.

Conclusion

There is a need to test power transformers in order to ensure safe, reliable and efficient operation. You are expected to test your transformer on a regular basis, i.e. according to the schedule and immediately in case of any warning signs, i.e. overheating, leakage of oil, strange noises or changes in voltage.

Routine testing, annual inspections and periodic diagnostic testing are used to identify the issues at the initial stages and avoid expensive failures. Safe operation is also well tested, particularly when assessing equipment condition in case of reuse or resale.

Through an appropriate testing regimen and addressing problems in the initial stages, industries can increase the life of transformers, minimize the downtime and get highly reliable performance of the power systems.